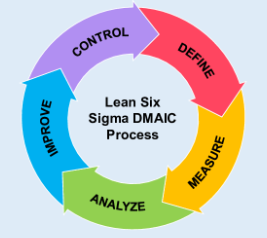

About Lean Six Sigma

Lean Six Sigma is a collaborative team effort to improve performance by removing waste and reducing variation. A series of phases organize the use of problem-solving tools to ensure that the true root causes are found and that a solution is fully implemented.

Lean Six Sigma at NC State University

Implementing Lean Six Sigma methodologies and culture in human resources at the University goes along with NC State University’s Strategic Plan Goals. Strategic Goal #5 is “Drive institutional effectiveness through transformative technologies, cutting-edge processes and actionable data focusing on efficiency and innovation.

Lean Six Sigma provides NC State University the tools to improve the capability of their business processes. The increase in performance and decrease in process variation helps lead to faster processes, increased customer satisfaction, improvement in profits, employee morale and higher quality of products and services.

Lean Six Sigma Committee

A Lean Six Sigma committee was created with a select group of University HR employees to help foster a culture of innovative thinking and inspirational problem-solving by embracing Lean Six Sigma principles. The committee encourages, cultivates, and embraces creativity and diversity in ideas and approaches to support the building of trusting relationships between UHR team members so that they feel comfortable to stretch beyond their normal work contacts to take on new challenges.

The Lean Six Sigma committee goal is to provide consultation to UHR departments and employees, providing resources and tools to help University HR and the HR community move forward on projects using Lean Six Sigma principles.

Lean Six Sigma Committee Members

- Matthew Carastro, College of Textiles

- Yasha Carter, UHR Information Management and Analytics

- Bernadette Clarke, UHR HR Service Center

- Ellen Coster, UHR Continuous Improvement

- Amy Grubbs, UHR Onboarding Center

- George Hibbler, UHR Information Management and Analytics

- Andy Riggs, UHR Classification and Compensation

- Lori Taylor, Provost Office

Lean Six Sigma Contact Information

Email: LSSCommiteee@ncsu.edu

Phone: 919-515-4294

5 Phases of Six Sigma: DMAIC

| 1. Define – Define the problem The first phase of the Lean Six Sigma Improvement process. In this phase, the project team creates a Project Charter and begins to understand the needs of the customers of the process. | Define Phase Examples: - Define Business Case - Define Problem Statement - Define Voice of Customer - Establish Baseline Project Metrics - Define objective statement and scope - Form Project Team - Identify financial impact - Complete project charter |

| 2. Measure – Quantify the problem How does the process currently perform? In this phase, the project team collects data and determines how the process currently performs. | Measure Phase Examples: - Map the process - Collect process data - Verify data integrity - Document process behavior - Baseline process capability |

| 3. Analyze – Identify the cause of the problem In this phase, the project team closely examines the process and looks for what might be causing the problem. | Analyze Phase Examples: - Cause and effect analysis - Identify root causes - Determine impact of root causes - Prioritize root causes |

| 4. Improve – Solve the root cause and verify improvement In this phase, the project team refines the process changes, implements solutions and collects data to confirm there is measurable improvement. | Improve Phase Examples: - Develop potential solutions - Evaluate and select best solutions - Pilot and implement solutions |

| 5. Control – Maintain the gains and pursue perfection In this phase, the project team tracks the success of the updated process and works to maintain the gains and continually update best practices. | Control Phase Examples: - Develop training plan - Implement solution - Identify lessons learned - Establish Process Measurements |

Training Opportunities in Lean Six Sigma

Lean Six Sigma In Person Training with College of Textiles

Yellow Belt

An introductory course to Lean Six Sigma. This course provides an overview of LSS roles and responsibilities, tools and concepts.

- Required for: All UHR SHRA and EHRA employees within their first twelve months of hire

- Days in Training: 2 Days – exam requirement for completion.

Green Belt

Will gain the skills needed to lead Lean Six Sigma process improvement projects and help their organization implement Lean Six Sigma effectively.

- Recommended for: SHRA/EHRA roles that have been with the University for 6 months or more and have taken the Yellow Belt or have past experience with Lean Six Sigma, those that are in a project focused role, or anyone interested in participating in projects and process improvement.

- Days in Training: 8 Days – Exam and Project requirement for completion.

Black Belt

Trained to identify opportunities for improvement with their organization, use Lean Six Sigma methodology and apply the correct tools and techniques to a Lean Six Sigma project.

- Recommended for: SHRA and EHRA employees that have been with the university for at least a year or more and have taken the Green Belt training, those that support/lead and identify opportunities for improvement, and anyone who will lead projects or is interested in providing statistical support and analytics around process improvement.

- Days in Training: 8 Days – Exam and Project requirement for completion.

Lean Six Sigma Online Training – LinkedIn Learning Path

LSS Foundation Courses

- Recommended for:

- employees who are in the queue for their Yellow Belt training to be scheduled or as refresher courses for anyone wanting to review.

- employees who are in the queue for their Yellow Belt training to be scheduled or as refresher courses for anyone wanting to review.

- Process Improvement Foundations (1hr, 18min)

- Improve Communication Using Lean Thinking (53 min)

- Six Sigma: White Belt (56 mins)

LSS Refresher Courses

- Recommended for:

- Anyone who has not participated in LSS projects and has recently been assigned to a LSS project and wants a refresher.

- Anyone who has completed certification and would like a refresher in different areas.

- Anyone who might be interested in pursuing their next level certification and wants a sneak peak at potential content and expectations.

- Lean Six Sigma Foundations (1 hr 10 mins)

- Lean Six Sigma: Define and Measure Tools (1 hr 25 mins)

- Lean Six Sigma: Analyze, Improve, and Control Tools (1 hr 21 mins)

- Six Sigma: Green Belt (1 hr 53 mins)

- Six Sigma: Black Belt (2 hr 30 mins)

Lean Six Sigma Resources/Toolkit

Project Idea

Have you identified an item for improvement that’s ready to go through the DMAIC process?

If your project is a “Just do it” you will not need to follow the steps below and can begin working on your project.

“Just do it” projects are simple projects like updating a webpage or a procedure. A “just do it” is a project that won’t take more than a month or two to complete and does not require system enhancements or campus-wide consideration/process improvements.

If you are not sure if your project goes through the DMAIC process, you can begin step 1.

Step 1 – Enter the Lean Six Sigma Process:

- To begin the process, complete and submit the LSS Project Consultation Form.

- After the form has been submitted, a member from the HR-Lean Six Sigma Committee will schedule a Project Intake Meeting with the submitter to clarify the project objectives, and additional information as needed.

- The Project will be reviewed by the HR Lean Six Sigma Committee and identify any issues, and concerns and make recommendations if this is a project or a “just do it.”

- LSS Committee will work with the project team on problem statement, mission statement, project charter and areas of opportunities.

- LSS Committee will help employees by guiding and approaching the problem solving process using the 5 steps of DMAIC.

- Lean Six Sigma Committee will work closely on providing resources and tools following the DMAIC process.

Step 2 – Enter the Project Management Process:

- The LSS Committee will work with the project team and PMO on Project Intake Form and any additional documentation needed for the project. To learn more about the Project Management office, please visit the website here.